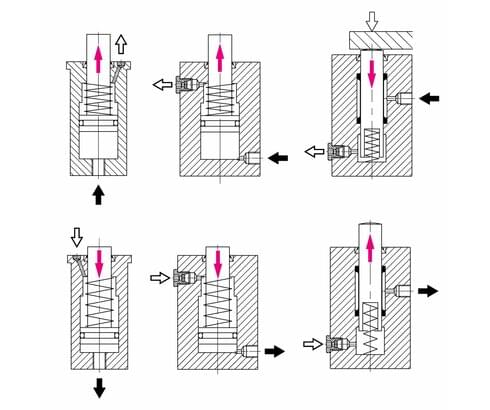

Venting of the spring area

Due to increased use of coolants and cutting fluids in metal cutting machining there is also an increased danger that some very aggressive fluids penetrate into the spring areas of single acting clamping elements and work supports, causing malfunctions.

It is important to realize these problems already in the period of design. The following versions show possible solutions to the above problems.

Why venting has to be made?

Excess pressure or depression

in the spring area change the spring forces which leads to malfunctions.

Formation of condensation water

promotes rust formation and can lead to a complete failure of the elements.

Leakages

of hydraulic seals must drain off to the exterior without pressure, otherwise there will be malfunctions.

Dust and swarf

are retained by sintered metal air filters.

Liquids

are the real problem, because they are drawn off through the air filter. Thereby the breathing spring area is reduced, a higher excess pressure or depression is caused and the function is impaired.

| Item no. | CAD data | type | |

|---|---|---|---|

|

Item no.

|

Properties

| ||

|

Item no.

|

Properties

| ||

|

Item no.

|

CAD data

|

Properties

| |

|

Item no.

|

Properties

| ||

|

Item no.

|

CAD data

|

Properties

| |

|

Item no.

|

Properties

| ||

|

Item no.

|

Properties

| ||

|

Item no.

|

Properties

| ||

|

Item no.

|

Properties

| ||

|

Item no.

|

Properties

|

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.