Zero point clamping system

STARK.classic.NG clamping elements are clamped with spring force and released hydraulically or pneumatically. Both hydraulic-releasing and pneumatic-releasing clamping elements are designed with zero point. A third-hand function is possible with hydraulic-releasing clamping elements. STARK.classic.NG clamping elements are also available with indexing and/or coolant outlet.

Special features of the STARK.classic.NG product family:

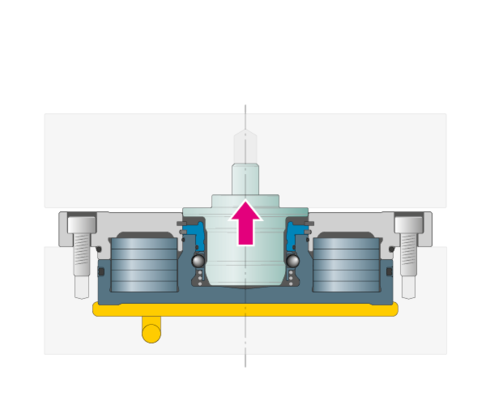

- lifting: STARK.classic lifts the pallet upon release

- simple: easy to clean

- precise: due to cylindrical fit

- durable: press-fitted bolts

- versatile: clamping control, seat check, blow-out, media duct

Detailed information on the STARK.classic.NG product family can be found in the catalogue download:

The STARK.classic.NG product family consists of three sizes STARK.classic.NG.1, STARK.classic.NG.2 & STARK.classic.NG.3 and offers a wide range of features and benefits.

Hydraulic-releasing elements

STARK.classic.NG clamping elements are clamped with spring force and released hydraulically or pneumatically. Both hydraulic-releasing and pneumatic-releasing clamping elements are designed with zero point. A third-hand function is possible with hydraulic-releasing clamping elements. STARK.classic.NG clamping elements are also available with indexing and/or coolant outlet.

Pneumatic-releasing elements

The pneumatic versions of the STARK.classic.NG product family are a useful addition to the hydraulic-releasing clamping elements. Particularly suitable for applications with low machining forces such as measuring machines, assembly applications or cleaning systems. For example, a device that has been clamped for machining with hydraulic-releasing clamping elements can be clamped easily and quickly for intermediate measurements or assembly work with pneumatic-releasing clamping elements.

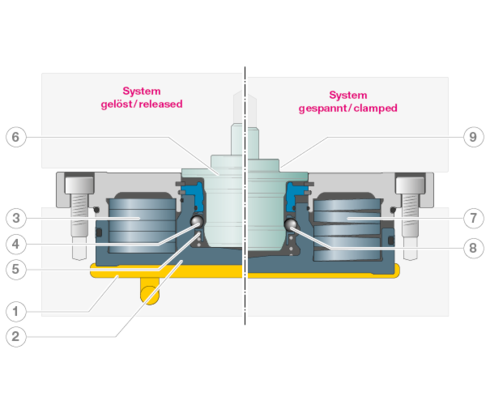

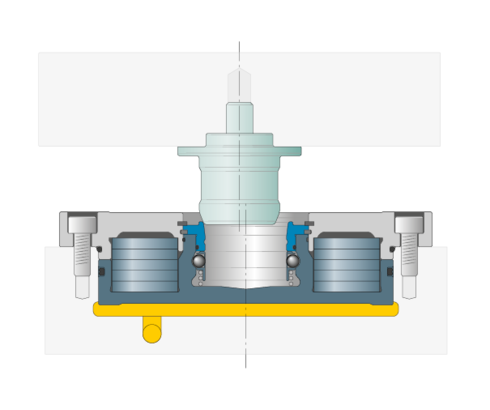

Hydraulic or pneumatic release:

- The piston (2) is subjected to the pressure (1) and moves upwards. The spring assembly (3) is compressed.

- The balls (4) in the ball retainer (5) move outwards to the parking position.

- The retractable nipple (6) moves into the fast closing clamp until it rests against the piston crown.

- The retractable nipple (6) is pre-positioned.

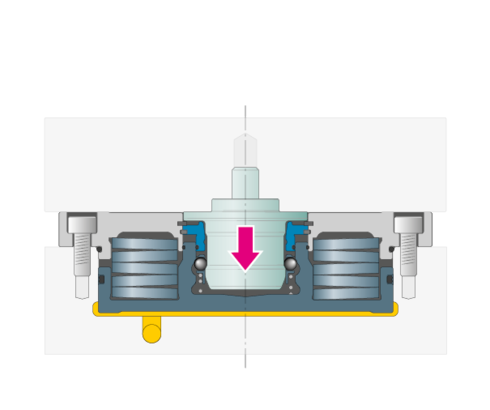

Mechanical clamping:

- The system is relieved and the pressure drops to 0 bar.

- The spring pre-tensioning force is initiated via the piston (2) which moves down.

- The fit is joined and the retractable nipple (9) is positioned with high precision.

- The balls (8) lie form-fitted between the piston and the retractable nipple in the contour provided.

- The pre-tensioning force of the springs (7) now acts directly and permanently downwards on the retractable nipple.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.