As an ambitious dental company with a keen sense of industry trends, Amann Girrbach develops, produces and distributes innovative equipment and materials to manufacture high-quality dental prostheses. A zero point clamping system from Stark Spannsysteme plays an essential role in their latest development. As a full-range supplier in the dental CAD/CAM sector, Amann Girrbach inspires dental technicians and dentists worldwide with comprehensive solutions.

The company offers integrated system solutions and products for the production of high-precision dental prosthetics, such as crowns, veneers, bridges and full dentures. The wide range of products covers the entire production chain. It includes computer-aided design and manufacturing (CAD/CAM) systems such as scanners, milling machines and software, associated consumables and classic dental prosthetics products for laboratories and dental practices.

More than 500 people are employed at six locations in Austria, Germany, the USA, Singapore, Brazil and China – and the number is growing rapidly. Amann Girrbach’s headquarters, research and development department and production are located in and around Koblach, Austria. The CAD/CAM sector with the globally successful product innovations of the Ceramill brand is proving to be a particular growth driver.

Ceramill Matik is an intelligent production solution that stands out from conventional milling machines with blank changers. As the first full service unit, it combines three machines in one. Besides the actual processing station, the unit also assumes the functions of a fully automatic warehouse management system and a machine cleaning device.

Another highlight is the newly designed 5-axis machining station. “With the Ceramill Matik, a new era is dawning in in-house production. A 5-axis machining centre with a 36-workpiece changer has never been seen on the market before. Comparable products have at most a 12-fold workpiece changer and are considerably more expensive,” says Marcel Humml, R&D design at Amann Girrbach. With this workpiece changer, the new Ceramill Matik has an unprecedented capacity. Supported by autonomous changing and cleaning processes, process-reliable milling operations overnight or at weekends are no longer a problem. A zero point clamping system from Stark Spannsysteme is used to ensure that these processes also function smoothly and safely.

Stark Spannsysteme from Rankweil (A) is considered a pioneer in the development and manufacture of zero point clamping systems and is the first company on the market that has specialised exclusively in this technology for decades. “The focus in developing the new Ceramill was clearly on unmanned production. We wanted to bring a certain efficiency to the dental laboratory. To make this work, we needed a system that could handle the many different tools and the most diverse materials unmanned. And that is only possible with a zero point clamping system,” says Humml.

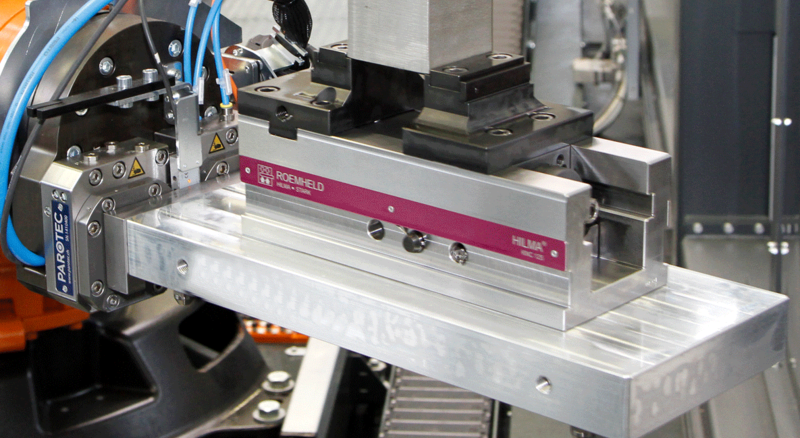

The first contact between the two companies came about at the opening ceremony of Stark Spannsysteme’s new building in Rankweil. “During the plant tour, Marcel Humml and I got to talking and he told me that he would like to use a zero point clamping system in his new machine. We then made an appointment at Amann Girrbach. He showed me the application. Together, we defined a specification sheet with the necessary parameters such as size, repeat accuracy, clamping force, process reliability, etc. One week later, I delivered our zero point clamping system of the type “STARK.basics.S Pneumatic”, says Michael Netzer, technical sales at Stark Spannsysteme.

The pneumatic STARK.basic.S is made of high-quality stainless tool steel and is ideally suited for this application thanks to its highly space-saving, compact and maintenance-friendly modular design. The positive clamping is fail-safe due to spring force and is released with pneumatics. Indexing is simple and reliable via an integrated, matched hole in the STARK.basic.S and a corresponding pin in the pallet. Since cleaning was given a high priority in this application, the decision was made to use the variant with intelligent blow-out technology for the zero point clamping system. The extending nozzle ensures particularly effective cleaning of the STARK.basic.S.

This is a basic prerequisite for reliable automation

The cylindrical bore remains free of swarf and due to the optimal force flow – the retractable nipples are permanently positively and highly precisely fixed by spring force – no bending or lifting is possible. Thus, also a high positioning accuracy is guaranteed. All this ensures optimal unmanned use. “When testing the zero point clamping system, we concluded that we would like to have a few modifications. We didn’t want any visible screws and the sides should be exposed so that the water and dirt could run off better. Due to our pallet size, we also wanted to reduce the support surface”, says Humml, who put these wishes to Stark’s development department.

“Classic machine and tool construction has always been a core competence of Stark. We probably have the most comprehensive product range on the market in the field of highly productive workpiece clamping. If the standard components do not lead to the goal, we develop individual and customised solutions for our customers. We always strive to find the best solution together with the customer. This distinguishes us and is undoubtedly also one of our core competencies”, Netzer continues.

The Ceramill Matik is also a novelty on the market in material management. All materials can already been read in at the incoming goods department or directly at the system and married to the intelligent holders. An electronically readable RFID chip in the holder makes it possible to read out all relevant material information inside and outside the machine at any time. The user always keeps an overview of the materials used and the handling effort due to the variety of materials, heights and shapes are significantly reduced. At the same time, the Ceramill Matik offers unprecedented capacity.

Supported by autonomous changing and cleaning processes, process-reliable milling operations overnight or at weekends are no longer a problem. “Quality assurance is very important to us. All the parts we use from Stark, i.e., the holder, nipple, master pallet and the calibration holder, are engraved with a serial number and thus guarantee complete documentation”, says Humml. “The master pallet is a ground plate and is needed to measure the machine. A 3-D probe automatically measures all positions. Thus, the machine calibrates itself automatically, which is an additional quality feature”, says Netzer.

Thanks to its high level of development expertise and consistent customer orientation, Amann Girrbach is one of the leading innovators and preferred full-service providers in digital dental prosthetics. Highest customer satisfaction and a constantly increasing number of partners in more than 90 countries worldwide speak for themselves.

“Thanks to the excellent cooperation with Stark, we were able to develop Ceramill Matik, a 5-axis production machine that is unparalleled in the market. The quality and the price-performance ratio of the Stark products fit, but above all the cooperation during the development phase was simply unbeatable – a customer relationship really couldn’t be better”, concludes Humml, and Netzer adds: “Our product came from the machining sector and was not originally intended for a small automation machine. But we have shown that we are also at home in medical engineering, which makes us all the more happy. In this industry, quality and precision are indispensable features – just like at Stark.”

We are here for you.

Do you have questions about your customer account, enquiries or orders? Please feel free to contact us.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.