Zero point clamping system

The STARK.airtec is a pneumatically operated zero point clamping system which, despite its compact external dimensions, generates maximum clamping forces. In addition to the simple versions with a flush-mounted and modular design, the STARK.airtec series also includes fast closing clamps that have an integrated querying unit.

Special features of the STARK.airtec product family:

- Low maintenance: intervals up to 2 million cycles

- Process reliability: Industry 4.0 ready

- Powerful: circulating clamping segments

- Precise: cylindrical fit

- Fast: clamping/release time 0.2 sec

Detailed information on the STARK.airtec product family can be found in the catalogue download:

Compact outer dimensions, mechanically clamped, pneumatically released

The products of the STARK.airtec series are fast closing clamps made of high-quality tool steel and optionally housings made of hard anodised aluminium with very small space requirements due to compact external dimensions. The system is mechanically tensioned with springs and pneumatically released. Circumferential clamping segments ensure that the retractable nipple is held optimally, securely and with positive locking all around in the fast closing clamp.

Many versions, integrated querying unit

Within the product family, a large number of design versions are available, which can be optimally used depending on the respective application area. In addition to the simple versions with a flush-mounted and modular design, the STARK.airtec series also includes fast closing clamps that have an integrated querying unit. In addition, the clamping status of the element can easily be recorded and signalled by means of three signals ("clamped without nipple",

"nipple clamped" or "released"). The module supports every application by means of LEDs directly on the back of the element as well as digitally for forwarding to a higher-level control system. The query is designed to be fail-safe and suitable for use in welding systems.

Optimised for use on machine tools

The products of the STARK.airtec family are optimised as zero-point clamping elements of the category "mechanical engineering" for use on machine tools and guarantee the highest repeat accuracy and process reliability. These products enable all common machining operations such as milling, grinding, eroding as well as the use on test benches and assembly devices. With the integrated "blow-out" cleaning function, the products can also be ideally used with automated loading.

Robot-supported loading and unloading

The product family has been extended with special versions designed for installation in systems for vehicle body shell construction, assembly systems and for connecting machine elements. Here, the focus is on robot-supported loading and unloading or the dynamic composition of devices in open space.

Additional functions using various retractable nipples

A wide range of retractable nipples is available to match the fast closing clamps that can provide additional functions (e.g. unique equalisation of ± 1.5 mm) or can be screwed into the device in a simple form depending on the application.

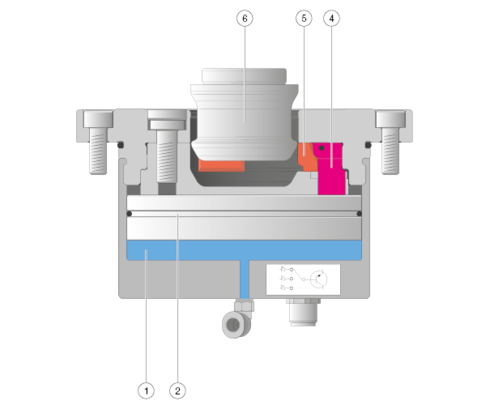

Single acting, pneumatic

The STARK.airtec is a pneumatically operated zero point clamping system.

The piston is held in the clamping position by springs – this piston has a single acting pneumatic design.

Release pneumatically:

- Pneumatic pressure (2) is applied to the piston (1) which moves upwards.

- The clamping fingers (4) are moved upwards by the piston (2) and pull the segments (5) outwards.

- The retractable nipple (6) is released.

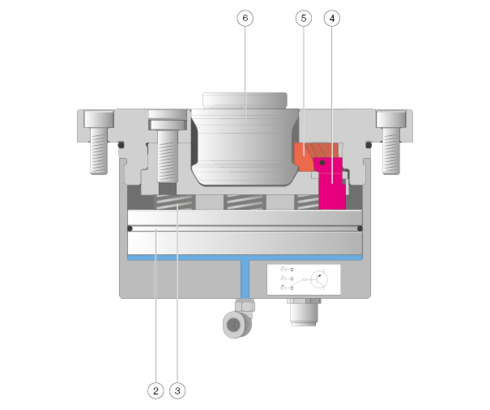

Clamp mechanically:

- The pneumatics are released. The pneumatic pressure drops to 0 bar.

- The spring pre-tensioning force 3 is initiated via the piston 2 which moves down.

- The clamping fingers 4 are pulled down by the piston 2 and push the clamping segments 5 inwards.

- The retractable nipple 5 is pulled down by the clamping surface on the clamping segments 6 and clamps on the support surface.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.