max. tensile force 100 kN, stroke up to 200 mm, vertical or horizontal design for suspension on a balancer

The new ROEMHELD bearing press is designed for inserting bearings into housing components. To simplify handling, the bearing press is available in a horizontal and a vertical version. For easy handling, the bearing press can be guided on a knuckle boom crane with a balancer.

Mounting on a trolley module is also possible. The new development is operated using a two-hand control. The pulling force of the cylinder can be adjusted within a range of 10 to 100 kN. The power unit and control unit can optionally be mounted on a crane column.

VIDEO OF THE BEARING PRESS

Get an all-round view of the new bearing press here.

-

ergonomic working thanks to suspension on a balancer (not included)

-

compliant with the Machinery Directive

-

process reliability thanks to adjustable joining forces and automatic sequence

Process, time and cost savings

In combination with our ergonomic assembly devices, a wide range of assembly processes can be completed in a single clamping operation. As the new ROEMHELD bearing press is mobile in contrast to a stationary press, it is particularly suitable for large and heavy components. This means that the reclamping or repositioning of the component, which is often necessary during joining processes, can be avoided. This results in a simplification of the processes and therefore also process, time and cost savings.

General description

The ROEMHELD bearing press is designed for inserting bearings into housing components. To simplify handling, the bearing press is available in a horizontal and a *vertical version. For easy handling, the new ROEMHELD development can be guided on a knuckle boom crane with a balancer. It can also be mounted on a trolley.

The device is operated by means of a two-hand control. The pulling force of the cylinder can be adjusted within a range of 10 to 100 kN. The associated power unit and the control unit can be mounted on a crane column as required.

Function | Joining process

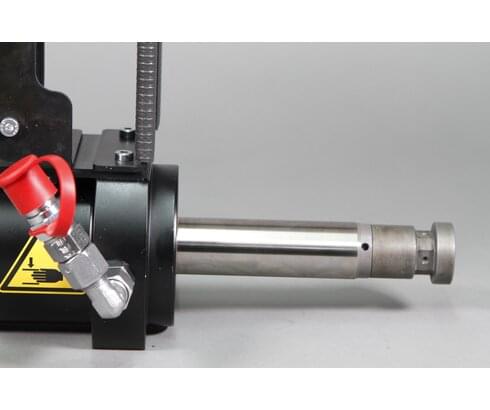

The bearing to be mounted is placed on the extended piston rod and picked up with the thrust piece at the front of the device. The piston rod is then passed through the bearing bore and a suitable thrust piece is placed on the end of the piston rod. After aligning and pre-centring the fixture with a low tensile force, the bearing can be retracted hydraulically. Various standard thrust pieces and extensions are available as accessories. Customised thrust pieces can also be manufactured if required.

bearing press

Control function

- setting the pulling force using the rotary switch

- set-up mode: retraction and extension using two-hand operation, direction preselection via rotary switch

- automatic mode: The cylinder retracts until the set force is reached and then automatically reverses direction and returns to the home position

- emergency stop switch with release on the unit

- switching between two adjustable pressure levels

moduhub - one system numerous possibilities

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.