Quick Ship

Over 200 of our most popular products available for immediate shipment from St. Louis, Missouri.

ROEMHELD North America’s Quick Ship products are a collection of our most popular core power workholding products that are in stock and ready to ship.

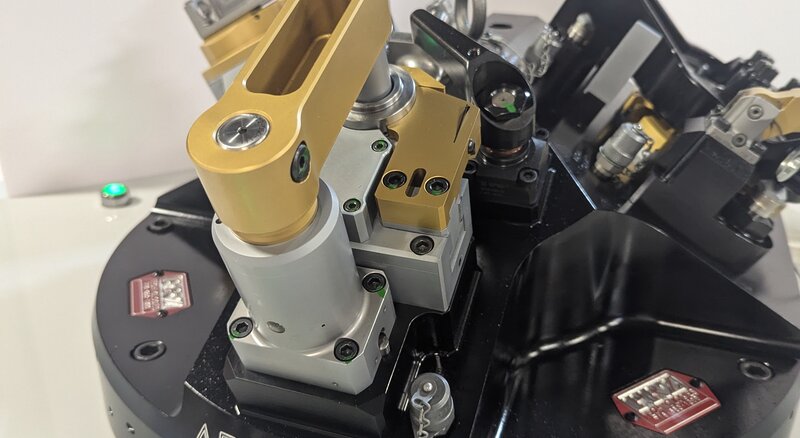

This collection consists of our most robust and popular products, including Threaded-Body, Block, Pull-Type, Hollow-Piston, and Low-Block Clamping Cylinders; Hinge, Compact, and Compact Swing Clamps; Threaded-Body Work Supports, and more.

What is power workholding?

Power workholding refers to the use of hydraulic and pneumatic clamping mechanisms specifically designed for securing workpieces during manufacturing processes. It represents a technological advancement over traditional manual clamping methods, offering a more efficient and automated clamping alternative for holding parts in place on machine tools.

This system is particularly favored for its ability to meet the demands for faster production rates and increased automation in modern manufacturing settings. Power workholding systems are characterized by their versatility, providing a wide range of options and capabilities, including automatic adjustment to workpiece irregularities, enhanced control, uniform operation, and reduced operator fatigue.

These benefits contribute to streamlined manufacturing processes, improved efficiency, and better overall productivity.

Take advantage of the free benefits of our login area:

- CAD data download

- Download operating instructions

Welcome back! Log in to your already existing user account.